Description

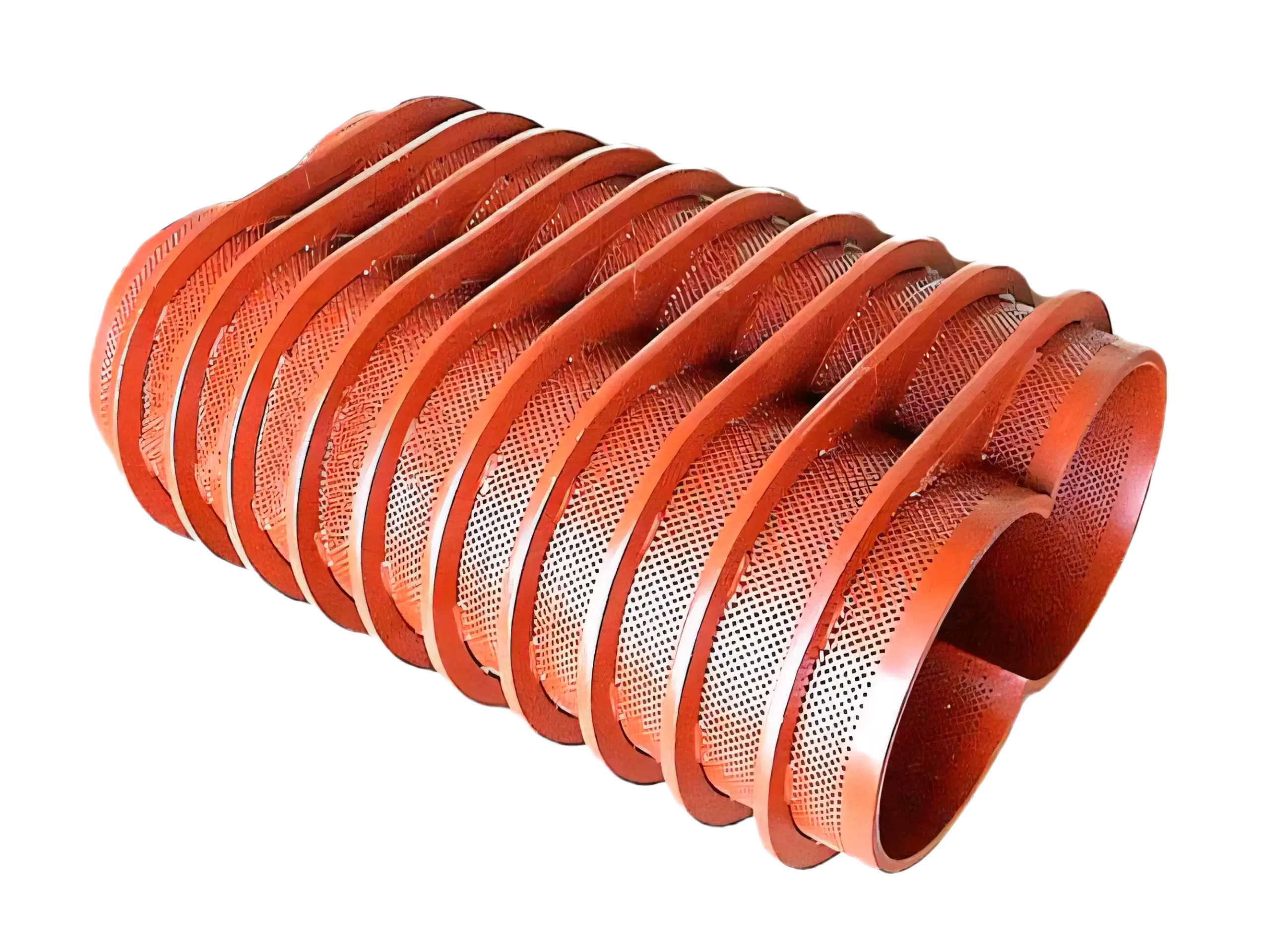

The Press Cage is a vital structural component of the EFB Press (Empty Fruit Bunch Press), designed to withstand high compression forces exerted by the Worm Screw Shaft during palm oil extraction. It ensures that the pressing process remains stable, efficient, and safe.

This heavy-duty enclosure channels the flow of EFB material, supports operational alignment, and contributes significantly to the separation of residual palm oil and moisture reduction, which are critical for downstream biomass or fertilizer applications.

🧩 Features of Press Cage

Withstands High Compression Force

Built to handle intense mechanical pressure without structural failure, ensuring continuous and reliable operation.Constructed from Wear-Resistant Materials

Made from high-grade carbon or alloy steel, providing resistance to friction and corrosion under extreme industrial conditions.Removable Design for Easy Maintenance

Allows for fast disassembly and reassembly for cleaning or part replacement, minimizing machine downtime.Controls Flow Direction of EFB Material

Guides EFB through the pressing system efficiently, reducing material dispersion and optimizing compression consistency.

🏗️ Types of Press Cage

Standard Press Cage

Suitable for conventional EFB press systems with standard throughput.Heavy-Duty Press Cage

Reinforced for high-capacity production lines requiring maximum pressure resistance.Custom-Made Press Cage

Tailored to specific press models or operational needs, with adjustable dimensions and material options.

🏭 Applications of Press Cage

Palm Oil Mills – Supports EFB compression for oil recovery and moisture reduction.

Biomass Power Plants – Enables low-moisture EFB suitable for use as biofuel.

Organic Fertilizer Plants – Produces EFB of optimal size and consistency for composting and soil amendment processes.

✅ Advantages of Press Cage

Enhances the efficiency and output quality of EFB pressing systems.

Minimizes wear on adjacent components by absorbing mechanical stress.

Durable and robust structure ensures long service life under harsh conditions.

Easy maintenance and servicing reduce downtime and labor costs.

Promotes uniform and precise EFB compression for optimal oil extraction.