Description

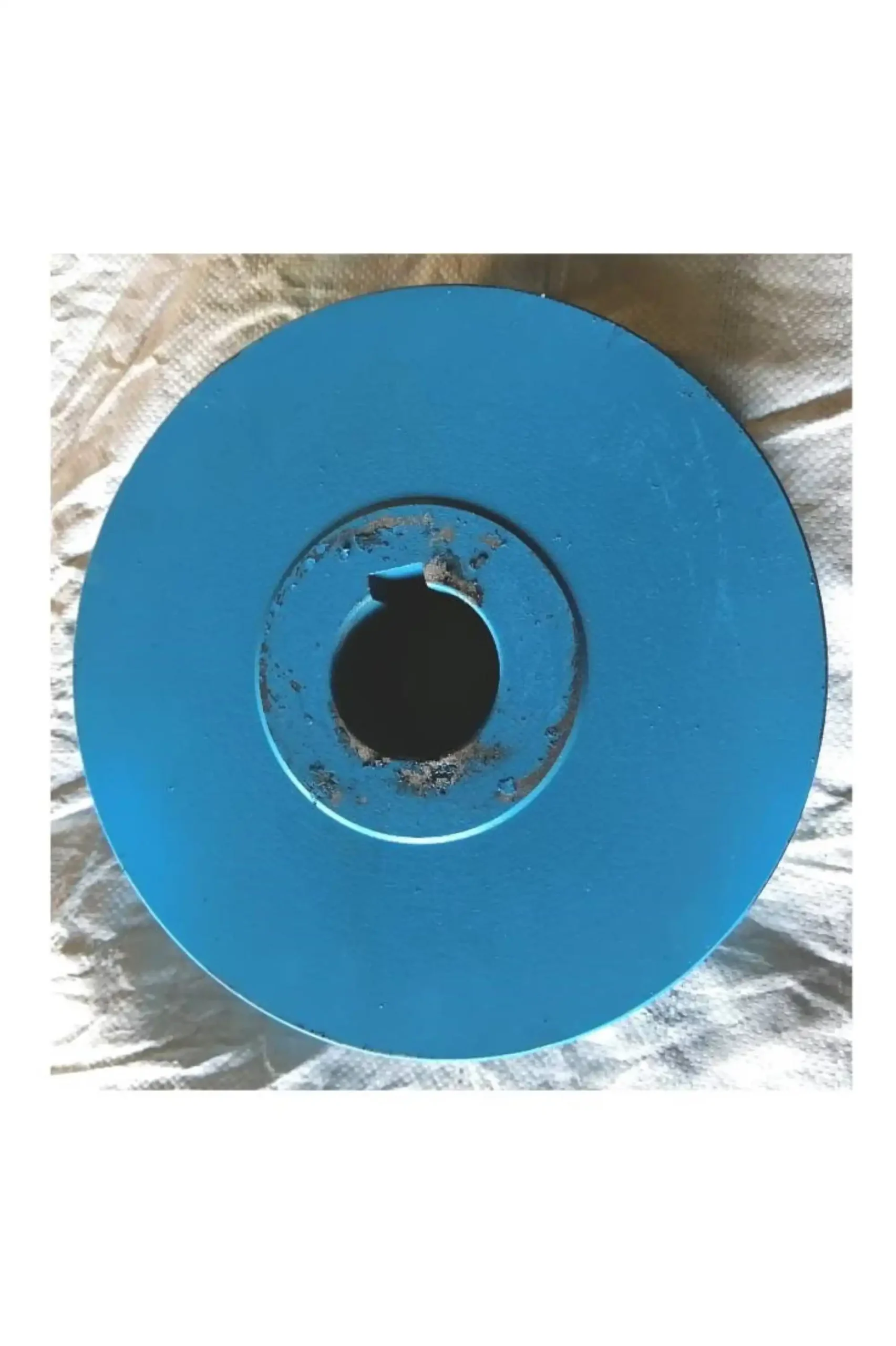

A Link Chain Sprocket is a critical component used in crane systems for lifting and tipping palm fruit bins in palm oil mills. It functions as a power transmission device that transfers torque from the motor to the crane chain, ensuring efficient, fast, and safe handling of fresh fruit bunches (FFB).

These sprockets are engineered to withstand high tensile forces and wear, making them ideal for heavy-duty operations in environments with high temperatures, humidity, and dust commonly found in industrial processing facilities.

🔩 Link Chain Sprocket Features

Precision Power Transmission

Designed for crane systems used in tipping and handling palm bins efficiently.High-Quality Wear-Resistant Materials

Made from carbon steel or alloy steel, heat-treated for superior durability and wear resistance.Handles Heavy Loads and High Tensile Stress

Built to resist deformation under high mechanical stress during crane operation.Enhanced Operational Safety

Minimizes slippage, improves stability, and ensures safer lifting processes.Seamless Compatibility with Endless Link Chains

Supports continuous operations and minimizes system downtime.

⚙️ Types of Link Chain Sprockets

Standard Link Chain Sprocket

General-purpose sprockets used with typical industrial crane chains.Hardened Steel Link Chain Sprocket

Heat-treated for increased resistance to wear and longer service life.Custom Link Chain Sprocket

Custom-engineered sprockets designed to meet specific operational needs or machine configurations.

🏭 Applications of Link Chain Sprocket

Palm Oil Mills – Used in crane systems to lift and tilt FFB bins during the sterilization process.

Heavy Industry Plants – Serves in conveyor or lifting systems handling large mechanical loads.

Steel & Metallurgical Industry – Assists in moving heavy steel products or scrap materials.

Cement Industry – Used in crane and conveyor systems dealing with heavy materials in extreme conditions.

✅ Advantages of Link Chain Sprocket

Ensures smooth and safe crane operation with accurate chain engagement.

Withstands high tensile stress and resists wear and corrosion in harsh environments.

Extends the lifespan of crane chains and minimizes maintenance costs.

Performs reliably under high-temperature, high-humidity, and dust-prone conditions.