Description

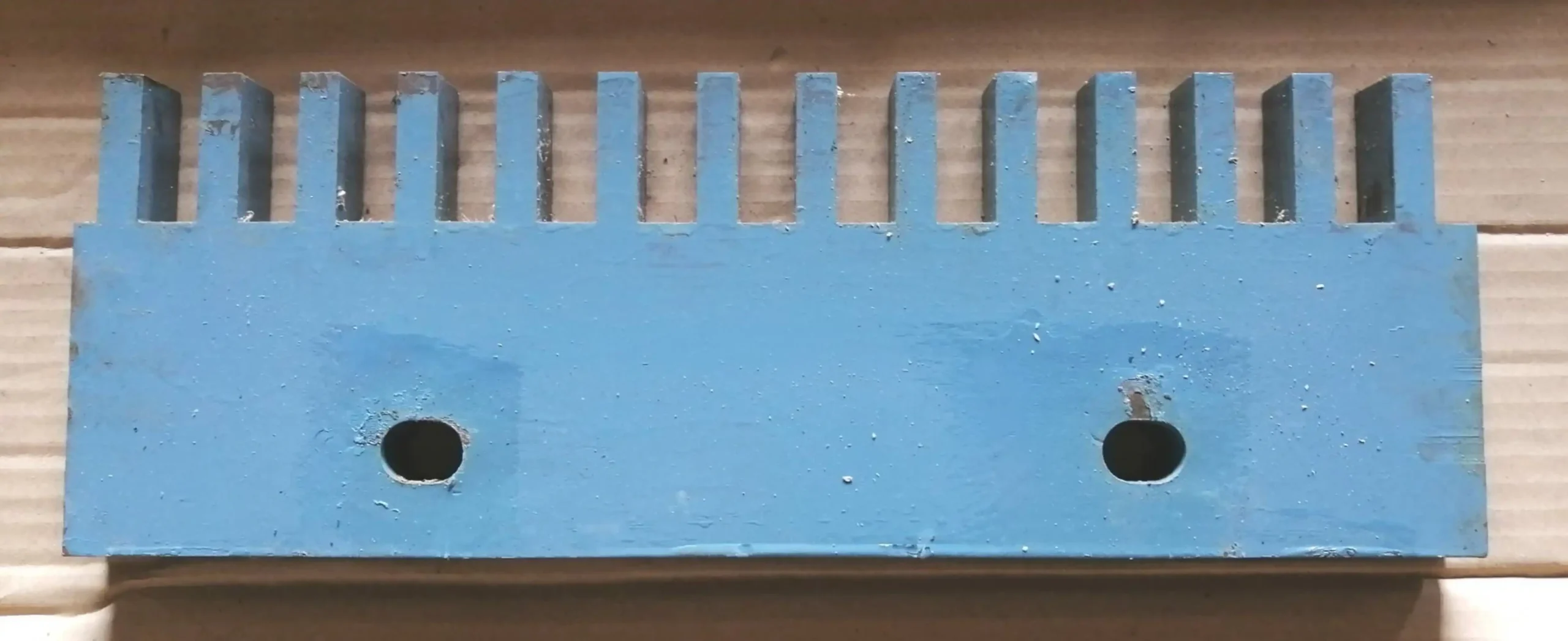

The Knife Bar is a key structural component in the EFB Shredder (Empty Fruit Bunch Shredder). It functions to secure and guide the Cutter Plates during the shredding process, ensuring that the palm empty fruit bunches (EFB) are chopped into appropriate sizes for use in biomass fuel, organic fertilizer, or other processing applications.

🔧 Knife Bar Features

Precision Blade Support and Directional Control

Holds the cutter plates firmly in place, ensuring accurate cutting and reducing EFB rebound during operation.Durable Material with High Impact and Abrasion Resistance

Made from hardened alloy or carbon steel, ensuring long service life under heavy-duty conditions.Designed to Withstand High Cutting Forces

Reduces vibration and enhances the overall performance and stability of the EFB shredder.Extends Cutter Plate and Machine Lifespan

Minimizes unnecessary friction and wear between the cutter and EFB materials.

🔩 Types of Knife Bar

Standard Knife Bar

Suitable for general-purpose EFB shredders in medium-scale operations.Heavy-Duty Knife Bar

Engineered for high-impact and continuous operations in large-scale industrial facilities.Custom-Made Knife Bar

Designed to fit specific machine configurations and specialized processing needs.

🏭 Knife Bar Applications

Palm Oil Mills – Supports the shredding of EFB for size reduction prior to downstream processing.

Biomass Power Plants – Enables EFB to be shredded to optimal size for use as biomass fuel.

Organic Fertilizer Plants – Assists in preparing EFB as raw material for composting and fertilizer production.

✅ Knife Bar Advantages

Enhances the precision and performance of cutter plates

Reduces friction and improves shredding efficiency

Withstands high pressure and impact, ensuring durability

Easy to install and maintain, minimizing machine downtime