Description

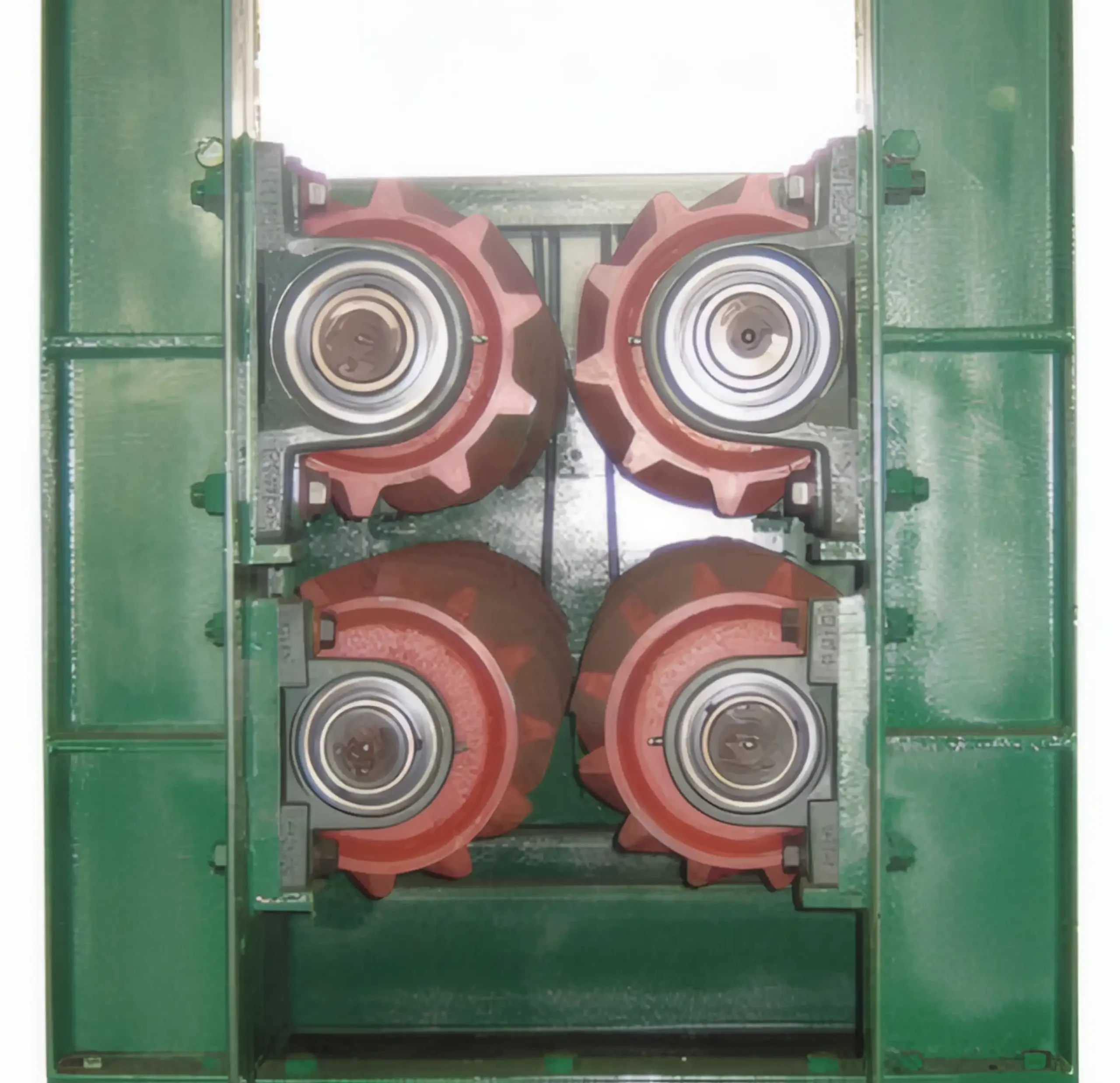

The Crusher Roller is a key component of the EFB Crusher (Empty Fruit Bunch Crusher). It functions as a heavy-duty roller that crushes and tears empty fruit bunches into smaller pieces, improving the overall efficiency of palm waste processing.

⚙️ Crusher Roller Features

Crushes and shreds EFB into smaller sizes

Reduces the thickness of EFB for easier handling and downstream processing.Made from high-strength, wear-resistant materials

Typically manufactured from manganese steel or high-carbon steel for superior durability.Supports continuous operation in large-scale mills

Designed to work efficiently with EFB Crushers and other integrated machinery.Minimizes maintenance costs

Engineered for long-lasting performance, reducing wear and the need for frequent replacements.

🛠️ Types of Crusher Roller

Single Roller

Used in small-scale EFB crushers.Double Roller

Suitable for medium to large EFB crushers with higher throughput.Heavy-Duty Roller

Designed for high-capacity crushing in large palm oil mills or biomass plants.

🏭 Crusher Roller Applications

Palm Oil Mills – Prepares EFB for further processing in crushing and shredding lines.

Biomass Energy Plants – Reduces EFB size for use as biofuel.

Organic Fertilizer Plants – Processes EFB into manageable size for composting or fertilizing.

✅ Crusher Roller Advantages

Effectively reduces EFB size for a wide range of industrial uses

Constructed from wear-resistant materials for extended service life

Suitable for high-volume production and heavy-duty industrial environments

Enhances the efficiency of EFB Crushers and helps lower operational costs